Laser cladding is a precision coating technology that uses a high-power laser to fuse premium metallic materials onto component surfaces to create a strong, wear-resistant, or corrosion-resistant layer without significantly heating the base material.

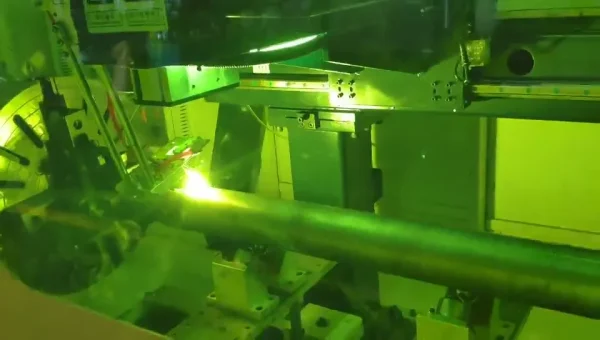

How the Enclosed System Works:

The entire cladding process occurs within a sealed chamber

A focused laser beam melts the feedstock material (powder/wire) onto the workpiece

The enclosed environment protects against oxidation and contaminants

Integrated exhaust systems remove fumes and particulates